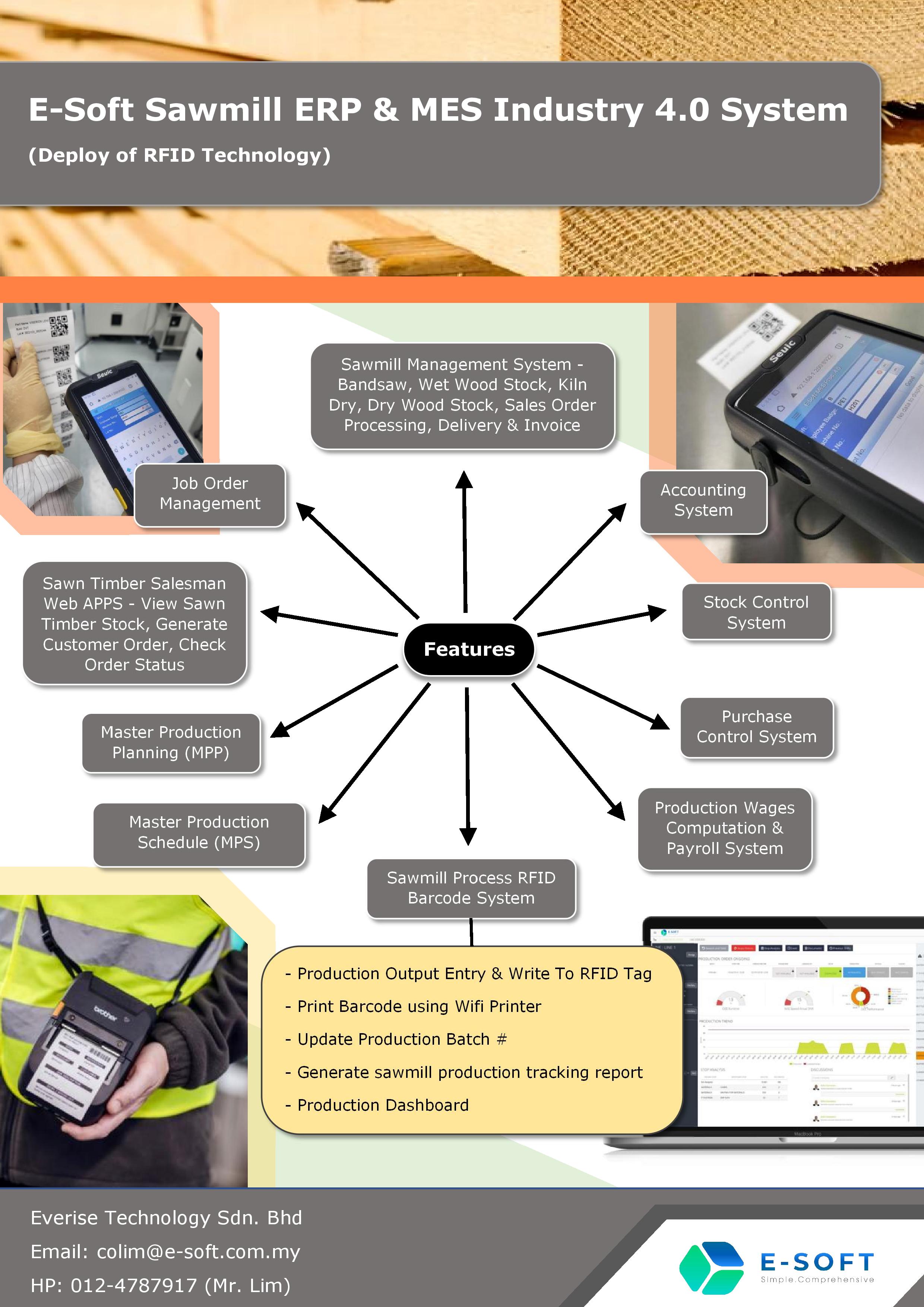

E-Soft Sawmill ERP & MES Industry 4.0 System

(Deploy of RFID Technology)

Software Features:

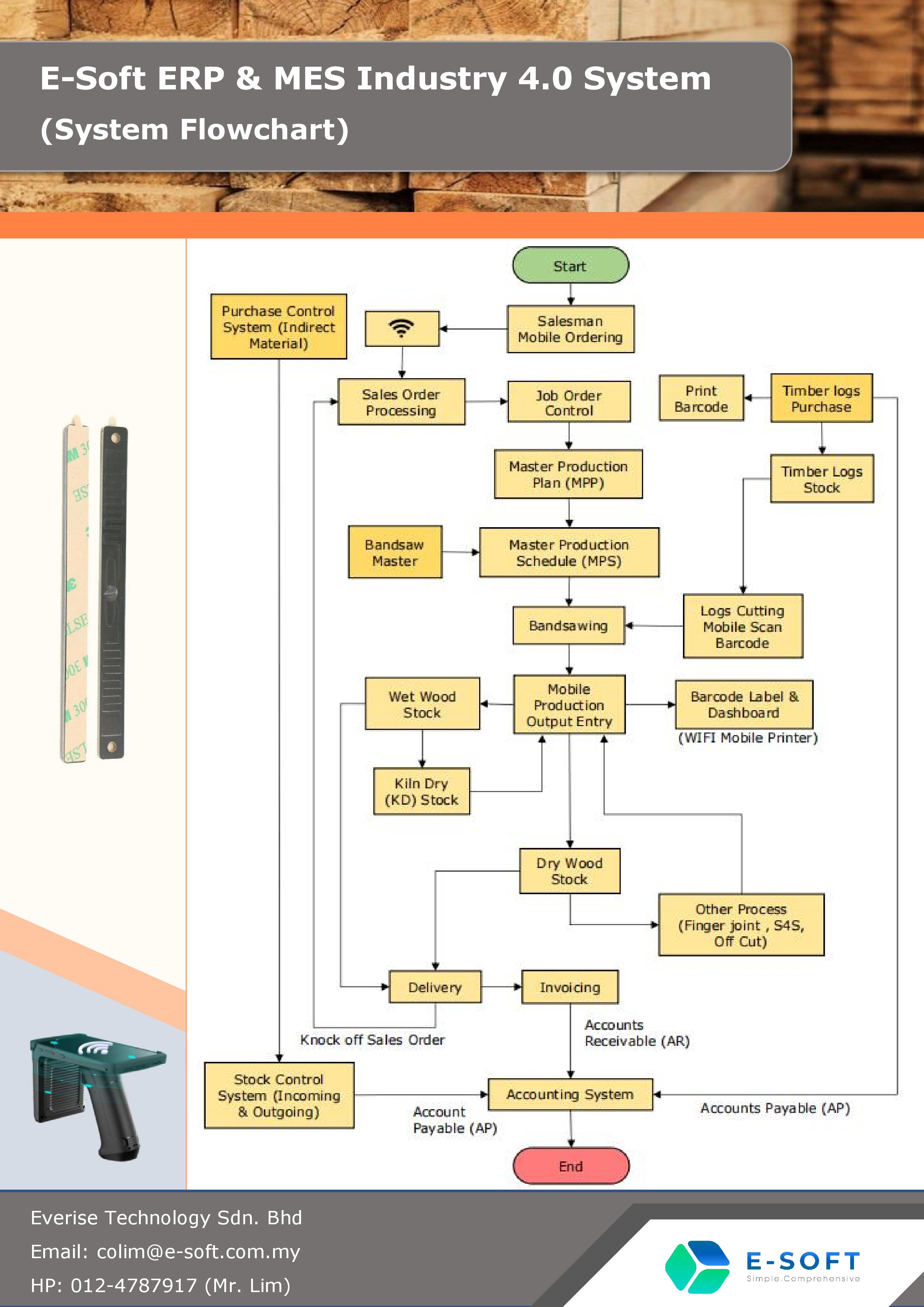

1. Sawmill Management System - Bandsaw, Wet Wood Stock, Kiln Dry, Dry Wood Stock, Sales Order Processing, Delivery & Invoice

2. Sawn Timber Salesman Web APPS - View Sawn Timber Stock, Generate Customer Order, Check Order Status

3. Job Order Management

4. Master Production Planning (MPP)

5. Master Production Schedule (MPS)

6. Sawmill Process RFID Barcode System

- Production Output Entry & Write To RFID Tag

- Print Barcode using Wifi Printer

- Update Production Batch No.

- Generate sawmill production tracking report

- Production Dashboard

7. Production Wages Computation & Payroll System

8. Purchase Control System

9. Stock Control System

10. Accounting System

- Timber Breakdown

- Sawmilling

- Pressure Treatment

- Kiln Dry Service

- Stacking

- Bundling

- Sawmill Wages